微隧道作业的理想结果是准确无误地安装了管道。 理想情况下,顶管也可以用作输送管,避免了额外的管子昂贵的衬套。 对业主而言,微隧道操作的最大好处是每根竖井尽可能使用的管道最长,系统一旦运行,每增加一个千斤顶,每英尺的线性成本就会下降。 弯曲的对准避免了障碍物和中间轴,从而延长了驱动长度。 但是,必须牢记有关顶管和管柱的一些关键方面,以确保所安装管道的质量完好。

Jacking Pipe and Pipe String: Key Factors to a Successful Curved Microtunnel

The desired result of a microtunneling job is a pipeline installed accurately and flawlessly. Ideally, the jacked pipe

serves as a carrier pipe as well, avoiding expensive sliplining of an additional pipe. The best benefit of a

microtunnel operation to the owner is the longest possible pipeline per shaft – once the system is running, the

cost per linear foot drops with every additional foot jacked. Curved alignments allow extended drive lengths by

avoiding obstacles and intermediate shafts. However, some key aspects regarding jacking pipe and pipe string

have to be kept in mind to ensure the flawless quality of the installed pipe.

RELATED: What Makes a Good Concrete Jacking Pipe?

Effect of Curves on Joint Articulation of Rigid Jacking Pipes

Today, tight curves in microtunneling are in most cases only possible with rigid, thick walled jacking pipes with

articulating joints, like reinforced concrete or polymer concrete. On a curved alignment, due to the rigidity of the

material, the deflection is concentrated in the pipe joints.

Figure 1: JC260 Hydraulic Joint installed on a 2,000 mm ID jacking pipe.

Pressure Transfer Keys

A high admissible jacking force is essential for an efficient operation and especially when things don’t go exactly

as planned, some reserves are desirable and should be part of the risk management. Even with the best

geotechnical investigation, any form of tunneling always involves surprises.

Safely transferring the jacking force from pipe to pipe in an articulated joint consequently is a key aspect and

necessary to understand the admissible jacking force without causing damage to the pipes.

Determining the admissible jacking force in an articulated joint depends directly on the material behavior of the

pressure transfer ring, therefore, predictable material behavior is key to a reliable calculation.

RELATED: Tualatin River Project Extends the Capabilities of Microtunneling

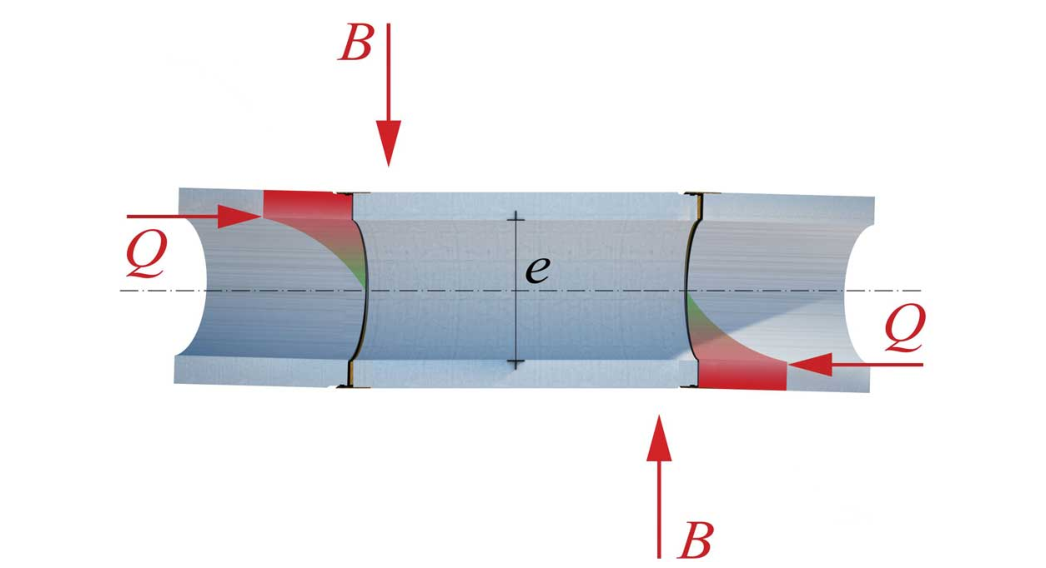

With conventional wooden pressure transfer rings, joint gaping on the outside of the articulated joint and point

loading and unpredictable stress peaks on the inside are the unavoidable consequences due to the hardly

predictable material behavior (Figure 2).

Figure 2: Stress distribution and eccentric loading with wooden pressure transfer ring.

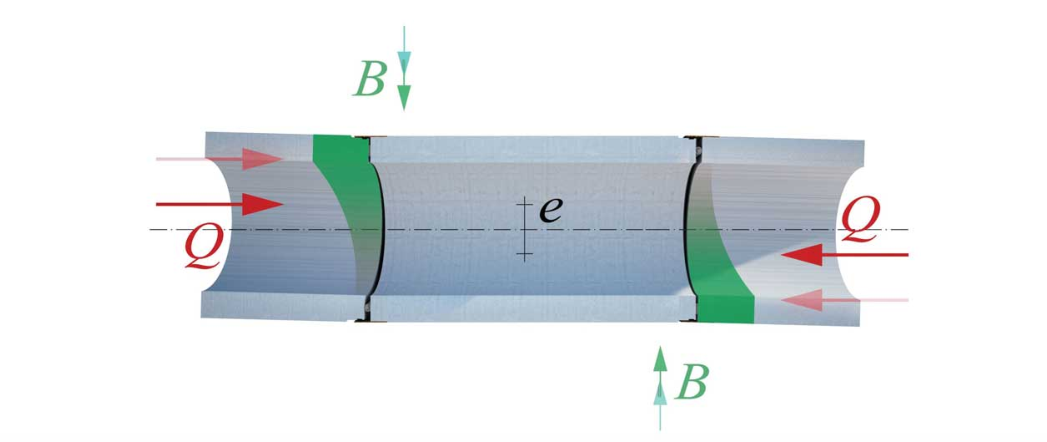

Engineered pressure transfer rings such as the Hydraulic Joint (Figure 1) or the EDAR can provide full face

pressure transfer without stress peaks even when large articulation angles are experienced and allow an exact

understanding of the stresses acting on the pipe due to their inherent, perfectly predictable mechanical behavior

(Figure 3).

Figure 3: Stress distribution and eccentric loading with Hydraulic Joint.

observed and should be considered. The eccentric axial loading is balanced by lateral forces acting on the

jacking pipes, significantly increasing the risk of damage.

The relevant eccentricity not only comes from the articulation of a single joint, but is the result of different joint

articulation angles on the front and back end of the pipe (Figure 2 and Figure 3). To minimize the eccentricity, a

suitable pressure transfer ring and smooth steering of the machine are key.

Jacking Pipe Keys

Apart from a robust structural design of the jacking pipes, the design of the pipe joints is important as the

articulation is concentrated in the pipe joints. The joint needs to be flush on the inside and outside of the pipe

and seal the pipe against groundwater and soil even in articulated state. With the requirement of predictable

behavior of the pressure transfer ring in mind, it’s key that the joint design seals the pressure transfer area as

well to avoid soil or water to unpredictably impact the behavior of the pressure transfer ring. A suitable joint

design consist of an external steel band or steel collar, cast into the concrete and a spigot end with the gasket in

a groove on the outside of the pipe. These considerations are also valid for designed straight drives as steering

corrections always force deflections on the pipe joints.

RELATED: Commonsense on a Curve

The joint articulation not only depends on the curve radius and the pipe diameter, but also on the pipe length.

Shorter pipes reduce the joint articulation angle at a given diameter and radius, but increase the number of joints

needed. Every joint is a weak spot in the pipe line and therefore the number of joints should be minimized. Also,

shorter pipe increase the cost per linear feet, not only on the manufacturing side but also during installation as

for every new pipe to be installed, all the utilities have to be disconnected and reconnected, leading to a slow

advance rate. The key here is to use pipes as long as feasible.

To accommodate the lateral forces due to eccentric loading, the structural design needs to provide enough

reserves. With a sophisticated monitoring system and the Hydraulic Joint as pressure transfer ring, the

admissible jacking force on every pipe at any location and articulation state can be determined in real time with

field measurements of the actual pressure and joint articulation the pipe is subject to. This way, the effective

stress state of every pipe under every circumstance during installation can be understood, which is the most

desirable key in risk management for a successful installation.

Alignment and Navigation Keys

The alignment of a microtunnel consists of straight, curved and transitioning elements. Curves require

navigation systems that can operate without line of sight between shaft and the machine.

Transitioning elements can be clothoids, which only gradually change the curve radius and not instantly as a

curve element right after a straight element would do.

Such transitioning elements can be implemented in sophisticated navigation systems, supporting the operator to

smoothly steer into the curve, therefore avoiding large differences in joint articulation over a short stretch, which

is typically the cause for reduced admissible jacking forces or pipe damages.

Key Aspects Summary

Predictable behavior of pressure transfer ring

Equal stress distribution and consequently low force eccentricities

Joint design with articulation capacity and sealing effect protecting the pressure transfer area

Sound structural design of the jacking pipe with reserves

Monitoring and understanding the stress state of the jacking pipes during installation

Smart alignment and navigation system, guiding the operator to smooth steering

沪公网安备 31011702006209号 技术支持:攸攸网络

沪公网安备 31011702006209号 技术支持:攸攸网络